Basement Ceiling Drywall Installation: 7 Pro Tips

Why Professional Basement Ceiling Drywall Installation Transforms Your Home

Basement ceiling drywall installation is a key step in changing an unfinished basement into valuable living space. The process involves hanging drywall sheets on ceiling joists, securing them, and finishing the seams to create a smooth, paint-ready surface.

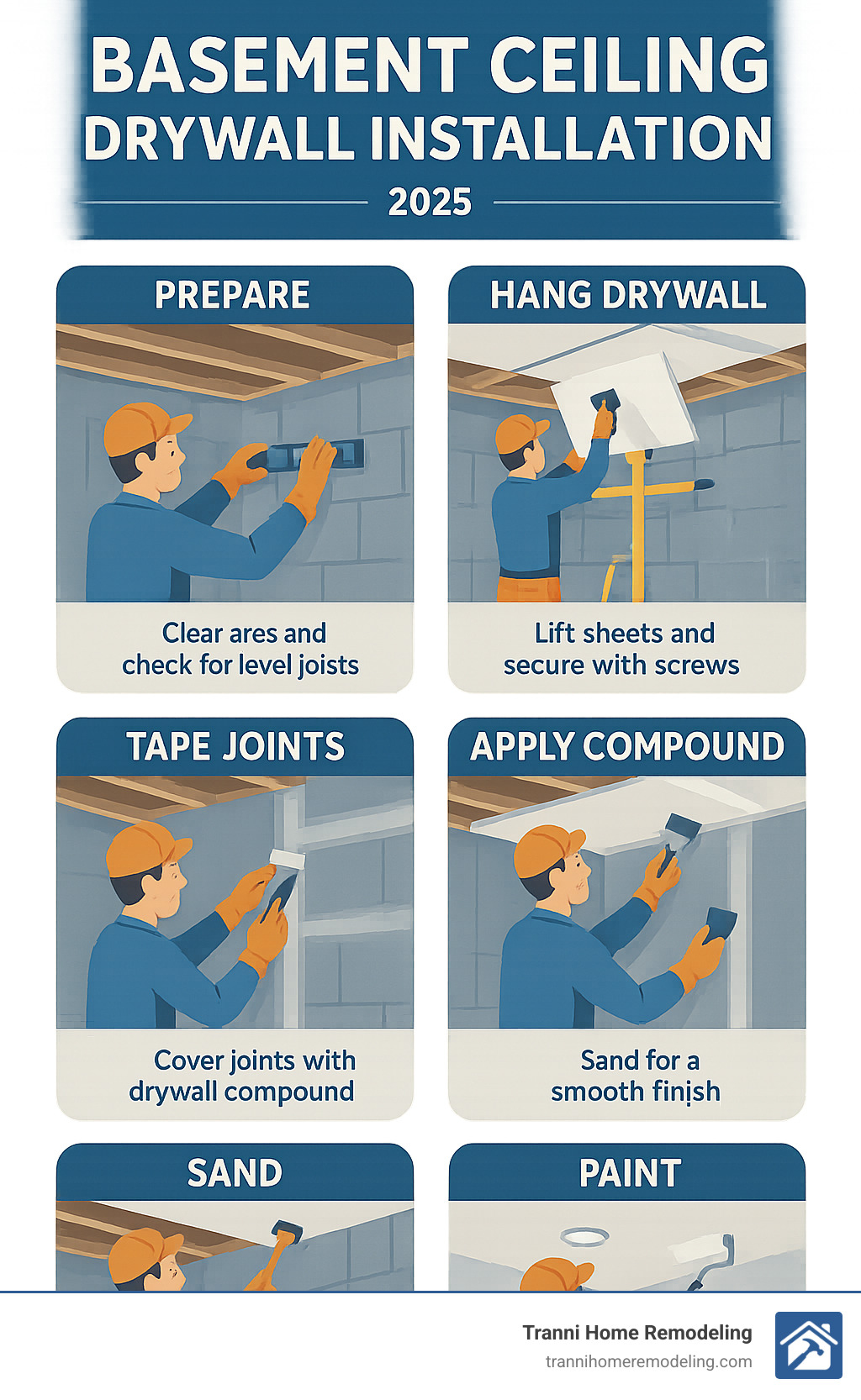

Quick Overview: Basement Ceiling Drywall Installation Steps

- Prepare the space – Clear the area and check for level joists

- Gather materials – 1/2″ or 5/8″ drywall, screws, joint compound, tape

- Plan your layout – Measure and mark joist locations, plan sheet placement

- Hang the drywall – Use a drywall lift, start with full sheets, secure every 12″

- Finish the joints – Tape, mud, and sand for a smooth surface

- Prime and paint – Complete the professional look

Many homeowners debate a DIY approach versus hiring professionals. While DIY can save around $2,000 on a 1,000 sq ft basement, drywall finishing is a technical skill. As one expert noted, it’s “almost an art form requiring experience,” and poor workmanship is highly visible, potentially lowering your home’s value.

The average cost for professional drywall installation ranges from $3,500 to over $12,000 for a 1,000 sq ft basement, depending on complexity. These are average internet-based costs and not specific Tranni Home Remodeling pricing.

I’m Tyler Tranni, owner of Tranni Home Remodeling. My team has helped countless homeowners in the Billerica area with their basement ceiling drywall installation projects, creating beautiful, functional spaces that add real value through expert craftsmanship.

Terms related to basement ceiling drywall installation:

Before You Begin: Key Decisions and Preparations

Proper planning is essential for a successful basement ceiling drywall installation. The preparation phase determines whether your finished ceiling looks professionally done or reveals costly mistakes. Before you begin, you’ll need to make key decisions about the ceiling type, materials, and joist preparation.

Drywall Ceiling: The Professional Choice for Basements

When finishing a basement, the choice often comes down to a drywall ceiling or a drop ceiling. While drop ceilings offer easy access to pipes, most homeowners prefer the clean, seamless look that only drywall can provide. A properly installed drywall ceiling makes a basement feel like a natural extension of your home’s living space, adding significant value and functionality.

| Feature | Drywall Ceiling Benefits |

|---|---|

| Aesthetics | Provides a smooth, continuous surface that makes your basement feel like an above-ground living space. No visible grid lines or that “office building” look – just a clean, finished appearance that you’ll actually want to show off to guests. |

| Cost | While the installation requires more skill and time, the material costs are often lower than a comparable drop ceiling system. Plus, you’re investing in a finish that typically lasts decades with proper installation. |

| Installation Quality | When installed by experienced professionals, drywall creates a superior, long-lasting finish that won’t sag or develop gaps over time like some ceiling tile systems can. |

| Access to Mechanicals | Here’s where planning really matters. Strategic placement of access panels ensures you can still reach critical systems for maintenance and repairs. Building inspectors are quite particular about maintaining code-required access to shut-off valves, electrical panels, and plumbing cleanouts. |

| Ceiling Height | Every inch counts in a basement, and drywall typically maximizes your available headroom – especially important if you’re already working with limited height. |

The key to making drywall work in basements with extensive mechanicals is smart planning. Our team excels at designing and building attractive soffits that neatly enclose ductwork and plumbing, creating clean lines that improve your basement renovations rather than looking like an afterthought.

Essential Tools and Materials for the Job

Having the right tools for basement ceiling drywall installation is critical for achieving professional results. Here’s a list of what you’ll need:

- Drywall Sheets: 1/2-inch or 5/8-inch thick. Larger sheets (4×12 or 4×16 feet) are preferable as they reduce the number of seams.

- Drywall Screws: Coarse-threaded screws for wood joists. Use 1-1/4 inch screws for 1/2-inch drywall and 1-5/8 inch for 5/8-inch drywall to ensure at least one inch of penetration.

- Drywall Lift: A non-negotiable tool for ceiling work. It safely holds heavy sheets in place, making the job manageable for one person.

- Cutting Tools: A T-square and a sharp utility knife for straight cuts. A rotary cutout tool is useful for openings.

- Fastening Tools: A cordless drill with a dimple bit to ensure consistent screw depth.

- Finishing Supplies: Joint compound, paper drywall tape (for strength), taping knives in various sizes, and a sanding pole.

- Safety Gear: Dust masks and safety glasses are essential.

- Marking Tools: A chalk line for marking joist locations.

Preparing Your Joists: To Strap or Not to Strap?

Many homeowners ask if they can screw drywall directly to the joists. The answer is maybe, but we usually recommend against it. Direct attachment only works if your joists are perfectly level and straight, which is rare in basements, especially in older homes throughout Middlesex County.

Furring strips or strapping is our preferred solution for most basement ceiling drywall installations. While it reduces ceiling height by about an inch and adds a step, the benefits are significant:

- Leveling Uneven Joists: By running 1×3 or 1×4 furring strips perpendicular to the joists and shimming them with a laser level, we create a perfectly flat plane for the drywall. This is crucial, as joists can vary by more than an inch.

- Better Screw Holding Power: Strapping provides more flexibility for screw placement and ensures every edge has proper support, reducing the risk of sagging or cracking.

- Sound Deadening: The small air gap can help reduce noise, especially when combined with insulation or resilient channels.

While direct attachment is faster, strapping is the professional method that ensures a durable, high-quality finish. It’s the right way to protect your investment in a finished basement.

The Step-by-Step Guide to Basement Ceiling Drywall Installation

With your planning complete, it’s time to hang the drywall sheets. This is where you’ll see your basement ceiling begin to transform.

Measuring and Cutting for Your Basement Ceiling Drywall Installation

Accurate measurements are crucial. Measure all four sides of the room, as basements are rarely perfectly square. Plan your layout to use the largest sheets possible (4×12 or 4×16 feet) to minimize the number of joints you’ll have to finish.

Begin against the longest, straightest wall. Snap a chalk line to ensure your first row is perfectly straight, as it will guide the rest of the installation. Always hang drywall sheets perpendicular to the ceiling joists or strapping for maximum support and sag prevention.

A key professional tip is to stagger your seams like bricks in a wall. Avoid aligning the butt joints (the non-tapered ends) in a single row. For cutting, use a T-square and utility knife to score the front paper, snap the board, and cut the back paper. For sheets spanning the room, subtract 1/4 inch from the measurement to ensure a good fit. A helpful technique for butt joints is to cut a slight V-groove on the edges to make taping and mudding easier. Use an online drywall calculator to estimate your material needs.

Hanging the Sheets: Professional Tips for a Quality Finish

This is the most physically demanding part of the basement ceiling drywall installation. A drywall lift is essential for this phase. It allows you to safely position heavy sheets overhead without assistance or risk of injury.

Start with a full sheet in a corner or along your straightest wall. Use the lift to press the sheet tightly against the ceiling and wall, aligning it with your chalk line. A simple T-brace made from scrap wood can help support the opposite end while you drive the first screws.

Work systematically by hanging all full sheets first, then cutting and fitting the smaller pieces. This method is efficient and minimizes waste. Each sheet should fit snugly without being forced into place.

Securing the Drywall: Fastener Best Practices

Proper fastening is critical for a lasting finish. We use drywall screws exclusively for their superior holding power, which is vital for ceilings.

Screw depth is key. Use a screw gun with a depth-setting attachment to drive the screw head just below the paper surface, creating a dimple without tearing the paper. A torn paper significantly reduces the screw’s holding power.

- Screw Spacing: Place screws every 12 inches along each joist or strapping member in the field (main body) of the sheet. Along the edges where two sheets meet, place screws every 12 inches, about 3/4 inch from the edge.

- Screw Penetration: Ensure screws penetrate at least 1 inch into the wood joist or strapping. Avoid over-driving them, as this damages the drywall core and weakens the hold.

Before finishing, do a final check. Remove any screws that missed the joist and sink any that are sticking out. This attention to detail is a hallmark of a professional basement ceiling drywall installation.

Working Around Obstacles and Achieving a Flawless Finish

Handling obstacles like ductwork, pipes, and electrical fixtures is what separates a professional finish from an amateur one. Basements are full of these challenges, and addressing them properly is key.

Planning for Lights, Vents, and Other Fixtures

Careful planning prevents costly cutting mistakes. Before hanging a sheet, create a detailed map of all fixture locations, measuring from at least two perpendicular walls. A simple trick is to apply lipstick or a dry-erase marker to the edge of an electrical box, then press the drywall against it to transfer the exact location.

For cutting, a rotary cutout tool is ideal for tracing around electrical boxes once the drywall is in place. For larger openings like recessed lights or vents, use a hole saw or jigsaw. Instead of awkwardly cutting around ductwork, we build custom soffits—framed boxes that enclose mechanicals. This creates clean, intentional lines and can even incorporate features from your basement lighting solutions, like recessed lights. Always use appropriate screw lengths and install metal protection plates over pipes and wires in vulnerable areas to prevent punctures.

The Art of Finishing: Taping, Mudding, and Sanding

The finishing process is what creates a perfectly smooth surface. Rushing this stage will result in visible imperfections that paint cannot hide.

- Taping: Apply a thin layer of all-purpose joint compound over seams and screw dimples. While wet, embed paper drywall tape, pressing it firmly with a 6-inch taping knife to remove air bubbles.

- Mudding: A three-coat process is standard. The first coat covers the tape. After it dries, apply a second, wider coat with a 10- or 12-inch knife, feathering the edges. The final topping coat is a very thin, wide layer using a lighter compound to smooth any remaining imperfections. This process creates the seamless look seen in professionally finished basements throughout Woburn and Winchester.

- Sanding: After the final coat is dry, sand the surface smooth. Start with medium-grit sandpaper on a sanding pole and finish with fine-grit. This creates significant dust, so proper ventilation, HEPA-filtered vacuums, and respirators are essential.

- Priming: The final step before painting is to apply a high-quality drywall primer. This seals the porous surfaces and ensures an even paint finish.

Best Practices for a Flawless Basement Ceiling Drywall Installation

Years of experience have taught us that details make the difference. Here are a few professional techniques:

- V-Grooving Butt Joints: Cutting a slight V-groove where non-tapered sheet ends meet creates a recess that is easier to hide with mud.

- Corner Bead: Use metal corner bead on the outside corners of soffits to create crisp, durable edges.

- Moisture-Resistant Drywall: In basements, we recommend purple board, which has a fiberglass mat that resists mold and mildew—a common concern in Middlesex County.

- Soundproofing: To reduce noise from the floor above, consider soundproof drywall or installing resilient channels and rock wool insulation in the joist cavities.

- Patience: Each coat of mud must dry completely before the next is applied. Rushing this process is the most common cause of a poor finish.

Frequently Asked Questions about Basement Drywall

Homeowners in Woburn, Winchester, and throughout Middlesex County often have similar questions about basement ceiling drywall installation. Here are answers to the most common ones.

What is the average cost to have a basement ceiling drywalled?

The cost to drywall a basement ceiling varies significantly based on the project’s complexity. For a 1,000 square foot basement, professional installation can range from $3,500 to over $12,000. The final price is affected by several factors, including the condition of the joists (extensive strapping adds cost), the number of soffits required for ductwork, and the type of drywall used (moisture-resistant or soundproof options are more expensive).

While a DIY approach might save around $2,000 in labor, drywall work is a skill. Poor workmanship is highly visible on a ceiling, and repairs can be costly. The figures mentioned are average costs based on internet data and are not specific pricing for Tranni Home Remodeling. We provide detailed estimates based on your basement’s unique conditions.

Is it better to hang drywall on the ceiling or walls first?

Professionals always hang the ceiling first. This method creates a tighter, better-supported joint where the top of the wall sheet butts up against the ceiling panel. If walls were installed first, fitting the ceiling drywall precisely would be much more difficult.

Installing the ceiling first also simplifies the taping and mudding process for the ceiling-to-wall corner. It establishes a clean, level line for the top of the walls, ensuring a more professional workflow and a better final result.

What thickness of drywall is best for a basement ceiling?

The choice is typically between 1/2-inch and 5/8-inch drywall.

- 1/2-Inch Drywall: This is the standard for most residential ceilings with joists spaced 16 inches on center or less. It is lighter, making it easier to handle for overhead work, and is more budget-friendly.

- 5/8-Inch Type X Drywall: We often recommend this for basements due to its superior benefits. Its thickness provides greater sag resistance, which is important for wider joist spacing (24 inches on center). It also offers significantly better fire resistance—a key safety feature since basements often contain furnaces and electrical panels. The added density also improves soundproofing between floors.

Building codes in some Middlesex County communities, such as Reading or Stoneham, may require 5/8-inch Type X drywall for fire safety. Always check local requirements before starting your project. The best choice depends on your budget, intended use, and local codes.

Conclusion: Is a Professional Drywall Project Right for You?

Basement ceiling drywall installation is a substantial project that can completely transform your home. It requires precision, patience, and physical stamina. The process, from hanging sheets to the multi-coat finishing work, can take weeks and demands a significant time commitment.

While the skill level required is not impossible, finishing drywall to a flawless standard is an art form developed through experience. Many DIY attempts result in visible seams, screw pops, and uneven surfaces that paint only highlights. While you might save money on labor, the risk of a subpar finish that detracts from your home’s value is high.

For homeowners in Woburn, Winchester, the North Shore, and throughout Middlesex County, local homes present unique challenges. Uneven joists, complex mechanical systems, and moisture concerns require experienced problem-solving.

At Tranni Home Remodeling, we bring over a decade of experience to every basement project. Our team has the expertise to handle any scenario, creating beautiful soffits and delivering the smooth, seamless finish that makes a basement feel like a true extension of your home. Professional installation provides peace of mind and expert craftsmanship that adds real, lasting value.

If you’re ready to transform your basement into a beautiful, functional space, let’s start the conversation. Your basement has incredible potential—let’s open up it together.

Get a professional quote for your basement finishing project today!

Like us on Facebook!